Bioplastics from Avocado Seed Starch : Effects of Chitosan and PVA on Mechanical Properties, Water Resistance, and Biodegradability

DOI:

https://doi.org/10.33096/jcpe.v10i1.1641Keywords:

avocado seed starch, bioplastics, chitosan, ployvinyl alcohol (PVA), mechanical propertiesAbstract

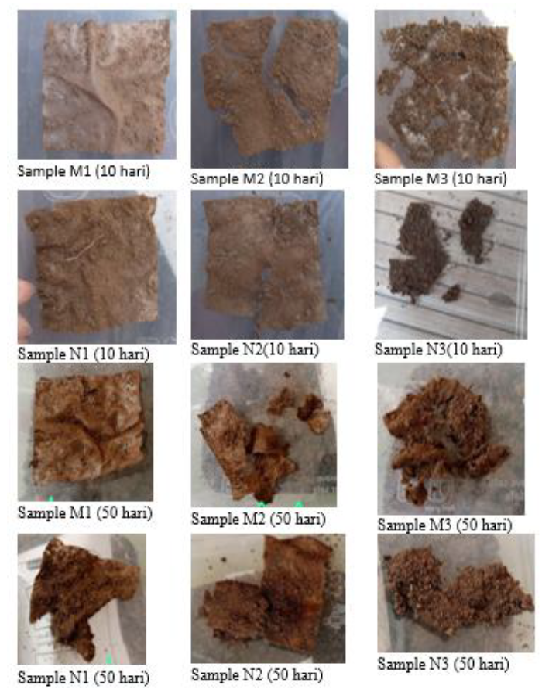

A sustainable alternative to traditional petroleum-based plastics, bioplastics produced from avocado seed starch can help alleviate some of the environmental challenges presented by plastic waste. However, these products still need to improve their mechanical properties and water resistance for industrial use. The purpose of this study is to find out how changes in the amounts of chitosan and polyvinyl alcohol (PVA) affect the mechanical strength, water resistance, and biodegradability of bioplastics made from avocado seed starch. The solution-casting method prepared starch-based bioplastics using chitosan (2.5–4.5 g), PVA (2.5–5%) as filler, and glycerol as a plasticizer. This study found that adding more chitosan increased the tensile strength, reaching a maximum value of 30.696±0.106 N/mm2 in the SNI 7188.7:2016, which was higher than the tensile strength value of the N3 sample. The samples N1 and M1 demonstrated the highest elongation at break of 35.700±4.776% and the lowest water uptake of 5.167%, indicating a 94.833% water resistance. The plastics underwent complete biodegradation under soil conditions after 60 days. This led to valuable results, confirming that avocado seed starch-based bioplastics, as engineering materials for food packaging, have enormous potential for application in the industry. This research needs to increase the water resistance or scale it up for industrial production

Downloads

References

[1] T. Muharam, D. Fitriani, D. Fataya Miftahul Jannah, M. Zidan Al Ghifari, and R. Pasonang Sihombing, “Karakteristik daya serap air dan biodegradabilitas pada bioplastik berbasis pati singkong dengan penambahan polyvinyl alcohol,” in Prosiding Seminar Nasional Aplikasi Sains & Teknologi (SNAST), Yogyakarta, 2022, pp. D35-49. doi: 10.34151/prosidingsnast.v8i1.4152.

[2] V. Fathurohman, D. Alisaputra, and E. Sedyadi, “The effect of addition of avocado fruit seeds on bioplastic biodegradation,” in Proceeding International Conference on Science and Engineering, 2020, pp. 137–145. doi: 10.14421/icse.v3.547.

[3] E. K. Rastini, S. Astuti, F. Handoko, and P. Vitasari, “Pelatihan pembuatan bioplastik untuk peningkatan kreativitas siswa di SMA Nasional Malang,” vol. 1, no. 1, pp. 7–13, 2020, doi: 10.36040/jasten.v1i1.3086.

[4] U.-Y. Kong, N. F. M. Rawi, and G. S. Tay, “The potential applications of reinforced bioplastics in various industries: A review,” Polymers, vol. 15, no. 10, p. 2399, 2023, doi: 10.3390/polym15102399.

[5] A. Ahdiat, “Komposisi sampah dari 96 kabupaten/kota Indonesia berdasarkan jenis,” 41% Sampah Indonesia berupa sisa makanan. [Online]. Available: https://databoks.katadata.co.id/datapublish/2024/03/26/41-sampah-indonesia-berupa-sisa-makanan

[6] S. A. P. Sari, R. O. Asriza, and A. Adisyahputra, “The influence of plasticizer type on the characteristics of bioplastics made from taro tuber starch (Colocasia esculenta (L.) Schott) with the addition of cane drague cellulose,” Kimia & Pendidikan Kimia, vol. 5, no. 2, pp. 285–296, 2023, doi: 10.20414/spin.v5i2.8211.

[7] L. Marlina and G. Nurhalliza, “Pengaruh variasi konsentrasi gliserol terhadap karakteristik biodegradasi dan water uptake bioplastik dari serbuk tongkol jagung,” vol. 15, no. 3, pp. 279–287, 2021, doi: https://ejournal.poltektedc.ac.id/index.php/tedc/article/view/527.

[8] R. Simarmata, A. Hartiati, and N. S. Antara, “Pengaruh pemlastis dan penguat polivinil alkohol terhadap karakteristik komposit bioplastik pati talas (Colocasia esculenta L) dan karagenan,” Jurnal Ilmiah Teknologi Pertanian Agrotechno, vol. 8, no. 2, pp. 77–90, 2023, doi: 10.24843/JITPA/2023.v08.i02.p02.

[9] S. Chadijah, H. Harianti, A. Febryanti, A. Alif, M. Maulidiyah, and A. A. Umar, “Synthesis of bioplastics on rice straw cellulose using orange peel extract, chitosan, and sorbitol,” Walisongo Journal of Chemistry, vol. 5, no. 2, pp. 111–119, 2022, doi: 10.21580/wjc.v5i2.10090.

[10] Z. Alves, N. M. Ferreira, P. Ferreira, and C. Nunes, “Design of heat sealable starch-chitosan bioplastics reinforced with reduced graphene oxide for active food packaging,” Carbohydrate Polymers, vol. 291, p. 119517, 2022, doi: 10.1016/j.carbpol.2022.119517.

[11] M. H. S. Ginting, R. Hasibuan, M. Lubis, F. Alanjani, F. A. Winoto, and R. C. Siregar, “Supply of avocado starch (Persea americana mill) as bioplastic material,” IOP Conf. Ser.: Mater. Sci. Eng., vol. 309, p. 012098, 2018, doi: 10.1088/1757-899X/309/1/012098.

[12] A. Hakiim and D. A. Sari, “Kajian karakteristik pembuatan edible film dengan kombinasi pati biji nangka dan alginat sebagai pengemas makanan berbasis biodegradable,” Jurnal Pangan dan Gizi, vol. 7, no. 2, pp. 124–131, 2017, doi: 10.26714/jpg.7.2.2017.124-131.

[13] K. Hayati, C. C. Setyaningrum, and S. Fatimah, “Pengaruh penambahan kitosan terhadap karakteristik plastik biodegradable dari limbah nata de coco dengan metode inversi fasa,” Jurnal Rekayasa Bahan Alam dan Energi Berkelanjutan, vol. 4, no. 1, pp. 9–14, 2020, doi: 10.21776/ub.rbaet.2020.004.01.02.

[14] S. Cengristitama and S. Ramlan, “Pengaruh penambahan plasticizer gliserol dan kitosan terhadap karakteristik plastik biogradable berbahan dasar pati sukun,” TEDC, vol. 16, no. 2, pp. 102–109, 2022. Retrieved from: https://ejournal.poltektedc.ac.id/index.php/tedc/article/view/579.

[15] T. U. Ani, I. Amri, and Z. Zultiniar, “Pengaruh perbandingan kitosan dan selulosa dari serat daun nanas (Ananas comosus) terhadap pembuatan bioplastik,” Jurnal Online Mahasiswa (JOM), vol. 6, no. 1, pp. 1–11, 2019. Retrieved from: https://jnse.ejournal.unri.ac.id/index.php/JOMFTEKNIK/article/view/23184/22447.

[16] M. Lubis, M. B. Harahap, H. S. Ginting, M. Sartika, and H. Azmi, “Production of bioplastic from avocado seed starch reinforced with microcrystalline cellulose from sugar palm fibers,” Journal of Engineering Science and Technology, vol. 13, no. 2, pp. 381–393, 2018. Retrieved from: https://jestec.taylors.edu.my/Vol%2013%20issue%202%20February%202018/13_2_8.pdf.

[17] A. Sofia, A. T. Prasetya, and E. Kusumastuti, “Komparasi bioplastik kulit labu kuning-kitosan dengan plasticizer dari berbagai variasi sumber gliserol,” Indonesian Journal of Chemical Science, vol. 6, no. 2, pp. 110–116, 2017, doi: 10.33394/hjkk.v8i1.2559.

[18] N. A. Adnan, S. H. M. Suhaimy, M. A. B. Pauzan, and B. Fauzi, “Effect of polyvinyl alcohol on cassava and potato starch plastic film: Mechanical, thermal and swelling properties,” Enhanced Knowledge in Sciences and Technology, vol. 3, no. 2, pp. 450–471, 2023, doi: 10.30880/ekst.2023.03.02.052.

[19] L. Ballesteros-Mártinez, C. Pérez-Cervera, and R. Andrade-Pizarro, “Effect of glycerol and sorbitol concentrations on mechanical, optical, and barrier properties of sweet potato starch film,” NFS Journal, vol. 20, pp. 1–9, 2020, doi: 10.1016/j.nfs.2020.06.002.

[20] I. A. Widhiantari, A. F. Hidayat, S. A. Muttalib, F. I. Khalil, and I. Puspitasari, “Sifat mekanik bioplastik berbasis kombinasi pati biji nangka dan tongkol jagung,” JRPB, vol. 9, no. 1, pp. 76–83, 2021, doi: 10.29303/jrpb.v9i1.220.

[21] P. Coniwanti, L. Laila, and M. R. Alfira, “Pembuatan film plastik biodegredabel dari pati jagung dengan penambahan kitosan dan pemplastis gliserol,” Teknik Kimia, vol. 20, no. 4, pp. 22–31, 2014, doi: 10.29303/jrpb.v9i1.220.

[22] A. Hartanti, M. N. Wahyudi, M. F. Hakim, A. R. Aeni, and D. A. Sari, “Characterization of biodegradable avocado seed starch films reinforced with chitosan and plasticized with glycerol,” Al-Kimia, vol. 13, no. 1, 2025. Retrieved from: https://journal.uin-alauddin.ac.id/index.php/al-kimia/article/view/55008.

[23] N. Ji, Y. Qin, T. Xi, L. Xiong, and Q. Sun, “Effect of chitosan on the antibacterial and physical properties of corn starch nanocomposite films,” Starch - Stärke, vol. 69, no. 1–2, p. 1600114, 2016, doi: 10.1002/star.201600114.

[24] D. f. Zatalini, P. Drake, E. Hendradi, and Sari Retno, “The effect of chitosan and polyvinyl alcohol combination on physical characteristics and mechanical properties of chitosan-pva-aloe vera film,” Jurnal Farmasi Dan Ilmu Kefarmasian Indonesia, vol. 10, no. 2, pp. 151–161, 2023, doi: 10.20473/jfiki.v10i22023.151-161.

[25] E. B. Slimane and S. Sadok, “Collagen from cartilaginous fish by-products for a potential application in bioactive film composite,” Marine Drugs, vol. 16, no. 6, p. 211, 2018, doi: 10.3390/md16060211.

[26] D. Liu, C. Zhu, K. Peng, Y. Guo, P. R. Chang, and X. Cao, “Facile preparation of soy protein/poly(vinyl alcohol) blend fibers with high mechanical performance by wet-spinning,” Industrial & Engineering Chemistry Research, vol. 52, no. 18, pp. 6177–6181, 2013, doi: 10.1021/ie400521a.

[27] G. M. Janeesh et al., “Enhanced electrical conductivity and structural, mechanical characterization of standalone poly(vinyl alcohol)‐graphite nanoplatelets composite films,” Journal of Applied Polymer Science, vol. 138, no. 10, 2020, doi: 10.1002/app.49976.

[28] Muh. Jufri, R. A. Lusiana, and N. B. A. Prasetya, “Effects of additional polyvinyl alcohol (PVA) on the physiochemical properties of chitosan-glutaraldehyde-gelatine bioplastic,” Jurnal Kimia Sains Dan Aplikasi, vol. 25, no. 3, pp. 130–136, 2022, doi: 10.14710/jksa.25.3.130-136.

[29] L. V. Cabañas-Romero et al., “Bacterial cellulose–chitosan paper with antimicrobial and antioxidant activities,” Biomacromolecules, vol. 21, no. 4, pp. 1568–1577, 2020, doi: 10.1021/acs.biomac.0c00127.

[30] R. Tahir et al., “Development of sustainable hydrophilic Azadirachta indica loaded PVA nanomembranes for cosmetic facemask applications,” Membranes, vol. 13, no. 2, p. 156, 2023, doi: 10.3390/membranes13020156.

[31] W. A. Bawazir, Q. A. Alsulami, and Sherif M. A. S. Keshk, “Augmentation in proton conductivity of crosslinked poly(vinyl alcohol) through the introduction of polyvinyl pyrrolidone,” Journal of Applied Polymer Science, vol. 140, no. 18, 2023, doi: 10.1002/app.53812.

[32] Maryam, M. S. Anwar, M. S. Kasim, and Santosa, “Utilization starch of avocado seed (Persea americana Mill.) as a raw material for dextrin,” Journal of Food Science and Engineering, vol. 6, no. 1, 2016, doi: 10.17265/2159-5828/2016.01.005.

[33] T. Nakano et al., “Adjustable biodegradability of low-swelling hydrogels prepared from recombinant peptides based on human collagen type 1,” Journal of Biomaterials Applications, vol. 37, no. 5, pp. 881–890, 2022, doi: 10.1177/08853282221123452.

[34] B. A. Harsojuwono, I. W. Arnata, A. Hartiati, Y. Setiyo, S. Hatiningsih, and L. Suriati, “The improvement of the modified starch—glucomannan—polyvinyl alcohol biothermoplastic composite characteristics with polycaprolactone and anhydride maleic acid,” Frontiers in Sustainable Food Systems, vol. 6, 2022, doi: 10.3389/fsufs.2022.844485.

[35] F. Xu et al., “Degradable, recyclable, water-resistant, and eco-friendly poly(vinyl alcohol)-based supramolecular plastics,” ACS Materials Letters, vol. 4, no. 6, pp. 1132–1138, 2022, doi: 10.1021/acsmaterialslett.2c00283.

[36] M. Karamanlioglu, R. F. Preziosi, and G. D. Robson, “Abiotic and biotic environmental degradation of the bioplastic polymer poly(lactic acid): A review,” Polymer Degradation and Stability, vol. 137, pp. 122–130, 2017, doi: 10.1016/j.polymdegradstab.2017.01.009.

[37] M. Kaseem, K. Hamad, and F. Deri, “Thermoplastic starch blends: A review of recent works,” Polymer Science Series A, vol. 54, no. 2, pp. 165–176, 2012, doi: 10.1134/s0965545x1202006x.

[38] J. Jin, M. Song, and D. J. Hourston, “Novel chitosan-based films cross-linked by genipin with improved physical properties,” Biomacromolecules, vol. 5, no. 1, pp. 162–168, 2003, doi: 10.1021/bm034286m.

[39] X. Weng, N. Lin, W. Huang, and M. Liu, “Fluorine-free compound water- and oil-repellent: Preparation and its application in molded pulp,” Coatings, vol. 13, no. 7, p. 1257, 2023, doi: 10.3390/coatings13071257.

[40] A. L. Lima et al., “Hot-melt extrusion as an advantageous technology to obtain effervescent drug products,” Pharmaceutics, vol. 12, no. 8, p. 779, 2020, doi: 10.3390/pharmaceutics12080779.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Journal of Chemical Process Engineering

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.